Plenty of work was accomplished this weekend, as stated in my last post, I filled the tank, put some base rock in and got the temp, salinity and pH up to par.

alt="">

On Thursday afternoon, I transfered some LR to start the biological filtration.

On Saturday, the yard was mowed, edged and cleaned, I was able to hang the canopy and put some of the live base rock, LR and corals into the tank:

alt="">

alt="">

alt="">

alt="">

Sunday I finished the CL, which is a PCX-55 w/ 2 penductors. Let me tell you, those things are quite powerful. There is plenty of flow in the tank now. I took a picture right after it was turned on, and you can see the amount of crud it stirred up.

alt="">

I'm still working on a full tank shot, since the lighting in the kitchen is a little bright. Here is one from the sink side of the kitchen after most everything was cleaned up.

alt="">

I still need to re-adjust the canopy to get it to hang better. In that last picture, you can see how it tilts slightly backwards. This is b/c all the cords are in the back of the canopy. I was thinking of adding some weights or something to the front of the canopy to pull it down. It may not be a big factor after the skirt is added though.

I did have one problem yesterday, after I was talking to my wife, I noticed that the bottom of one of the baffles had come loose, fuge side. As I as walking into the kitchen, the baffle broke free from the silicone, splashing a little h2o on the floor. Nothing major, but now I need to figure out if I need to drain the sump and fix it. I did learn one big lesson though, silicon DOES NOT stick to HDPE. Anyone have any ideas?

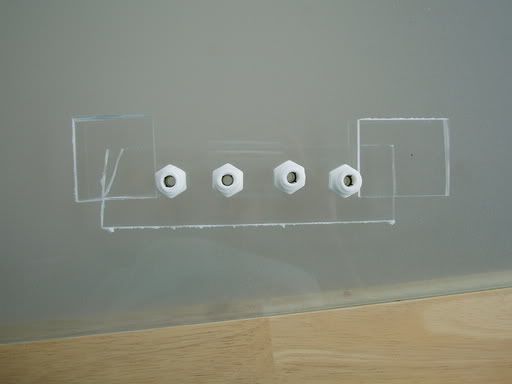

alt="">

You can see where the baffle used to be (marked w/ white silicone). It came free of the glass and now has moved a couple of inches to the left, towards the return pump. Not much has been effected by it, although, it does mess up what I was going to do for my auto-top off.

I'm also dealing w/ some heat issues, I guess those 2 PCX-55 pumps add a few degrees of heat to the tank. I have 2 diff thermometers running, but they don't agree. One says ~ 82 and the other is around ~84. I need to put a fan over the sump when I get that fixed.

Thanks for looking.

Chris