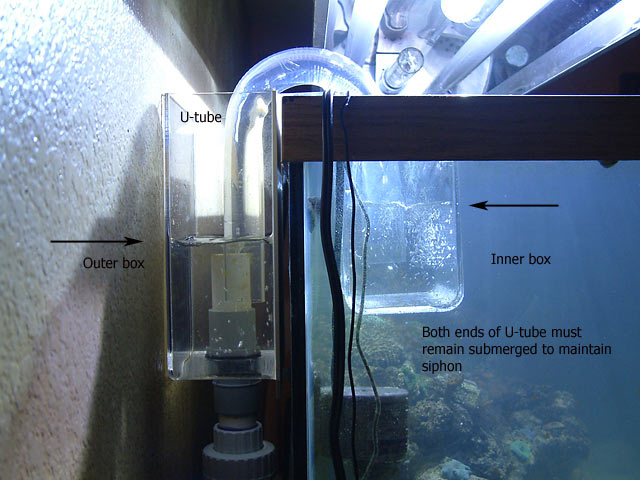

I'm building a new overflow and wiere, I don't like the one I made originally, it was somethign I kind of threw together from parts I had laying around. It works fine, but it looks horrible. I as thinking about making one like the one Meelve made on his D.I.Y. page, but the wier is too big to fit between the tank and the wall. so I was wondering if there is a claculation to determine the proper hight and width or does it not so much matter as long as it doesn't over fill and run out all over the floor. Also I was wondering if it's too far below the overflow if that will cause it to overfill faster than it can drain off. I did find out that if both the over flow and the wiere are the same dimensions that the amount of water in the overflow will be directly proportional to the amount of water in the wiere. Example would be if the overflow was 4x4x4 and the wiere is also 4x4x4 and there is 2 inches of water in the over flow at any given time then there will be 2 inches of water in the wiere at any given time. Would thi also be correct no matter the size of either?