mitch91175

Premium Member

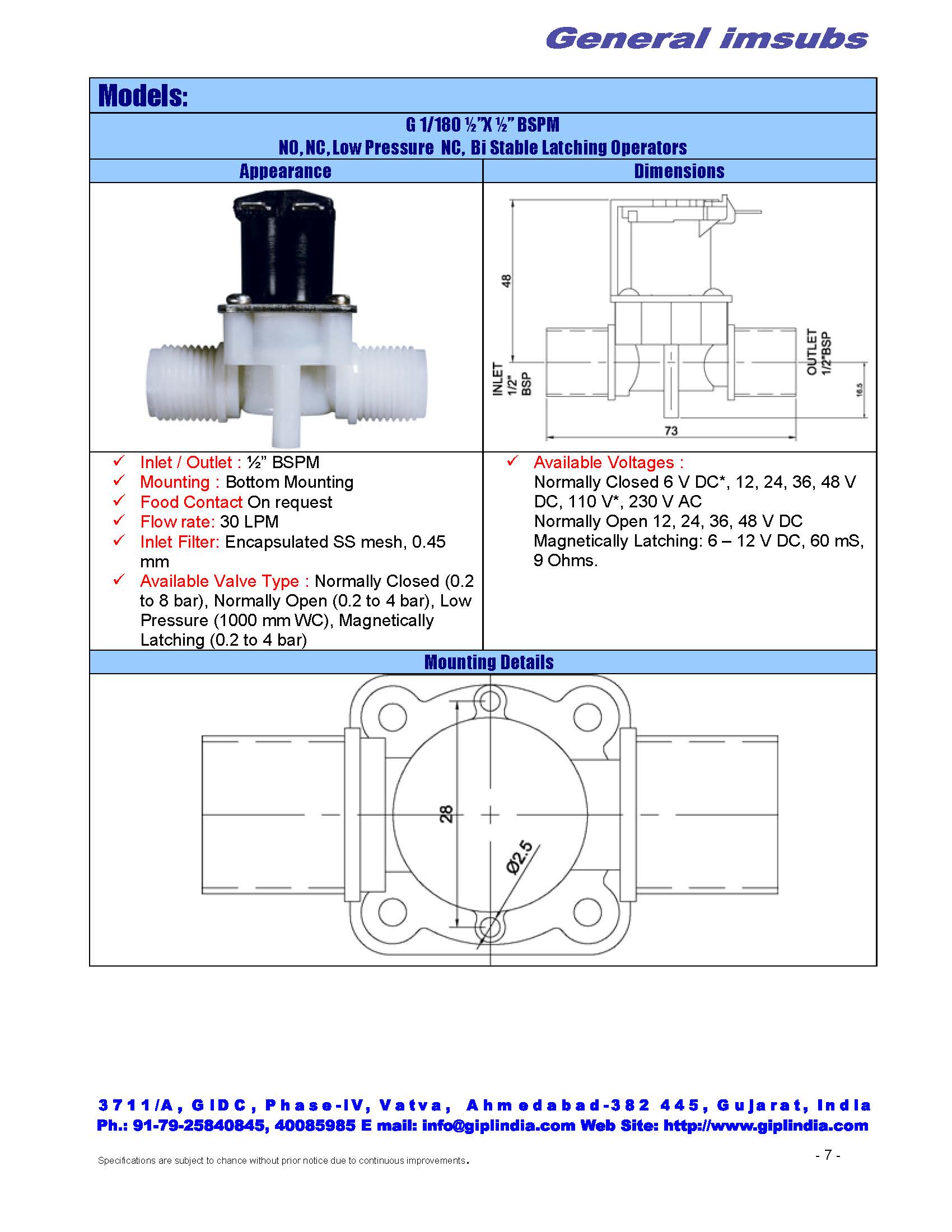

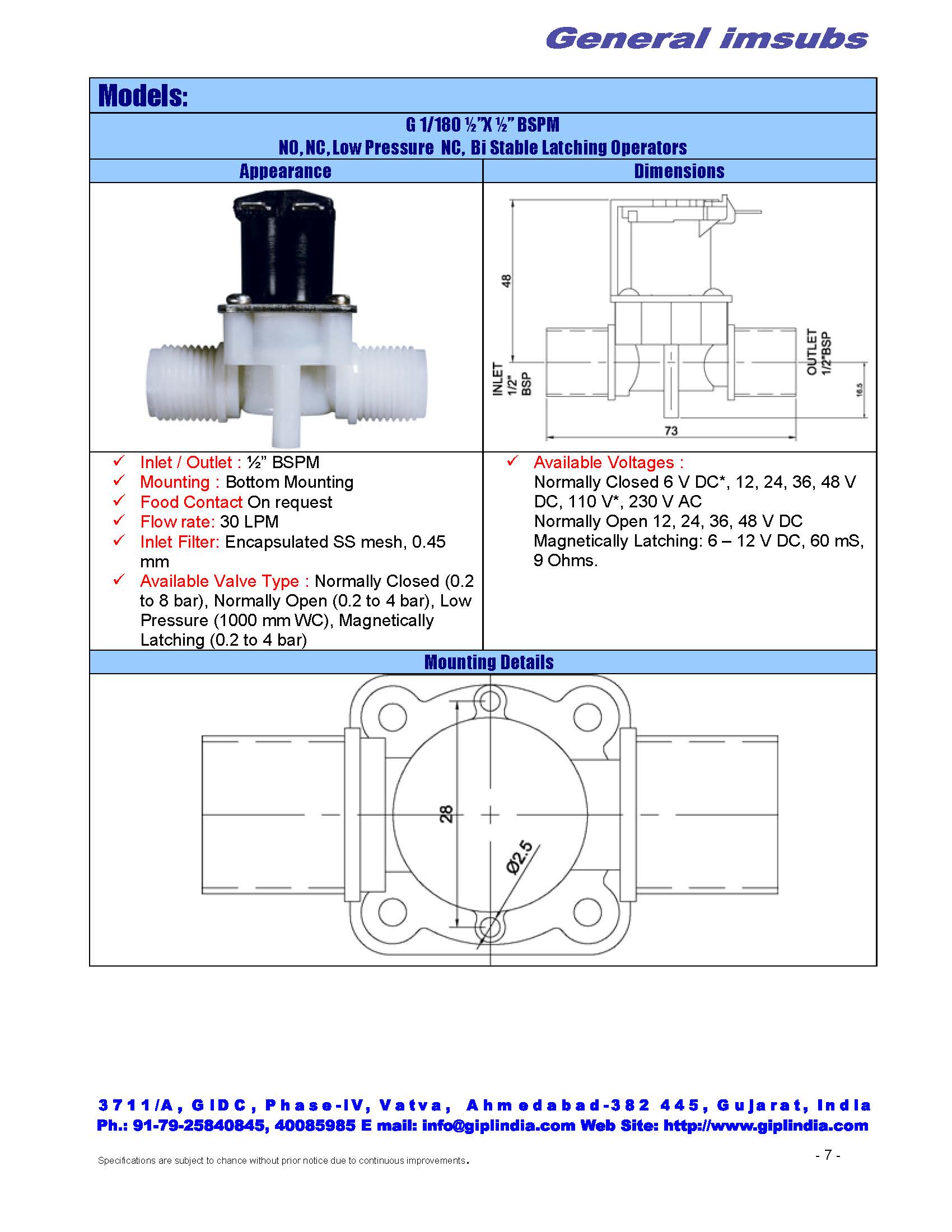

I have a calc reactor being fed off my secondary manifold. I would like to have my AC3Pro stop feeding water to the calc reactor if my pH reached a certain level. First question is do I need to stop feeding the calc reactor water (CO2 already being controlled by AC3) in order not affect pH levels in my tank? Second if so (without having to get a separate pump) what is a good solenoid to use to stop the water flow to the reactor?

Would something like this accomplish what I am trying to do: http://www.giplindia.com/G1180-1-2inch-specs.htm

alt="">

alt="">

Or will this work better (http://www.giplindia.com/domestic-RO.htm):

alt="">

alt="">

I also found this: http://www.fishbowl-innovations.com/product/solenoid

alt="">

alt="">

Would something like this accomplish what I am trying to do: http://www.giplindia.com/G1180-1-2inch-specs.htm

Or will this work better (http://www.giplindia.com/domestic-RO.htm):

I also found this: http://www.fishbowl-innovations.com/product/solenoid