[From a discussion earlier that I pretty much hijacked I decided to start a new thread about a remedy to bubbles in my tank.

I saw the video of a tower with LR that Marc had created on his website that seemed to work well. But, last night at the meeting he stated he had a couple of other ideas.

Marc could you please expand? Also, if anyone else has some ideas fire away!

Here is my dilemma:

I have a 90g tank and not alot of space under for a sump. So, I converted my old 29g into one. This contains my skimmer, skimmer pump (submerged Dolphin 1200) and a few baffles.

My return pump is a GenX that is rated at 1200gph. My estimates are it's pushing around 800gph after head loss. So, I've got some serious flow that I really don't want to reduce if I don't have too.

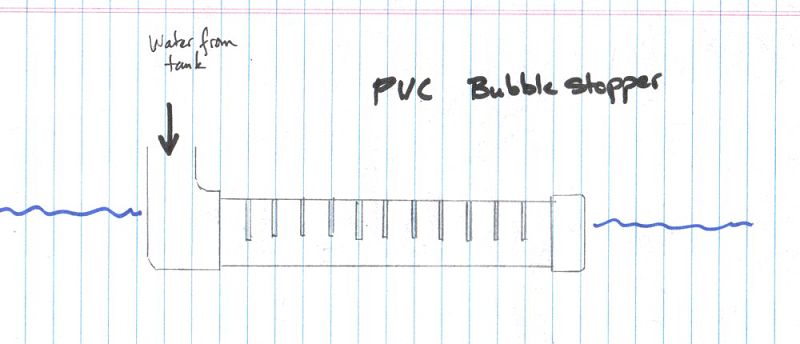

This past weekend I added two more baffles that took alot of the bubbles out of the main system. But, the drain line produces a crazy air/water mixture that I beleive if I can break up prior to the baffles should really help.

Check out the pics in my gallery HEREover on RC. Please note that these pics are not updated, but you get an idea of how my sump is setup.

Thanks for any help.

Kurt]

Edited By Modo on 1092327316

I saw the video of a tower with LR that Marc had created on his website that seemed to work well. But, last night at the meeting he stated he had a couple of other ideas.

Marc could you please expand? Also, if anyone else has some ideas fire away!

Here is my dilemma:

I have a 90g tank and not alot of space under for a sump. So, I converted my old 29g into one. This contains my skimmer, skimmer pump (submerged Dolphin 1200) and a few baffles.

My return pump is a GenX that is rated at 1200gph. My estimates are it's pushing around 800gph after head loss. So, I've got some serious flow that I really don't want to reduce if I don't have too.

This past weekend I added two more baffles that took alot of the bubbles out of the main system. But, the drain line produces a crazy air/water mixture that I beleive if I can break up prior to the baffles should really help.

Check out the pics in my gallery HEREover on RC. Please note that these pics are not updated, but you get an idea of how my sump is setup.

Thanks for any help.

Kurt]

Edited By Modo on 1092327316